“Robotics has been around forever, and it’s been the next big thing forever, and it is so exciting and compelling that it’s easy to get carried away. People almost always do, and that’s one of the things that has held back the industry”, said Colin Angel, former CEO of iRobot.

Robotics is already transforming all kinds of sectors, but its effects are especially impactful in areas like construction, characterized by repetitive tasks, inefficient processes, and the handling and movement of large amounts of heavy materials, often on hostile surfaces.

A study by the University of Illinois at Urbana-Champaign and the Midwest Economic Policy Institute states that in the U.S., nearly half of construction jobs could be replaced by robots by 2057. The digital revolution is evident in this sector, with technological solutions driving change, even in an industry where many processes have remained unchanged for a century.

More Efficiency Without Compromising Quality

Robotics will transform the future of construction, improving work quality, optimizing processes and productivity, and enhancing efficiency and sustainability.

On construction sites, robots handle physically demanding and exhausting tasks, minimizing errors and the risk of injury to workers. They not only enhance safety but also ensure that projects are delivered on time, reducing waste, delays, and stalled executions.

The history of construction robots dates back to the 1960s. Although these early robots were bulky and limited, programmed for tasks such as masonry, concrete pouring, and excavation, they laid the foundations for future advances in ‘automated construction’.

After initial modest innovations, the construction robotics industry is now booming. It is estimated to reach $383.11 million in 2024 and grow at an annual rate of 15.5% until 2029, reaching an expected value of $787.84 million.

The Types of Robots in Construction Today

The robotics industry equips the construction sector with a diverse set of tools. These include robots that automate the placement of building elements, autonomous vehicles for material transport and excavation, arms for façade inspection, high-precision drilling machines, and 3D printing robots for complex structures.

Here are some examples:

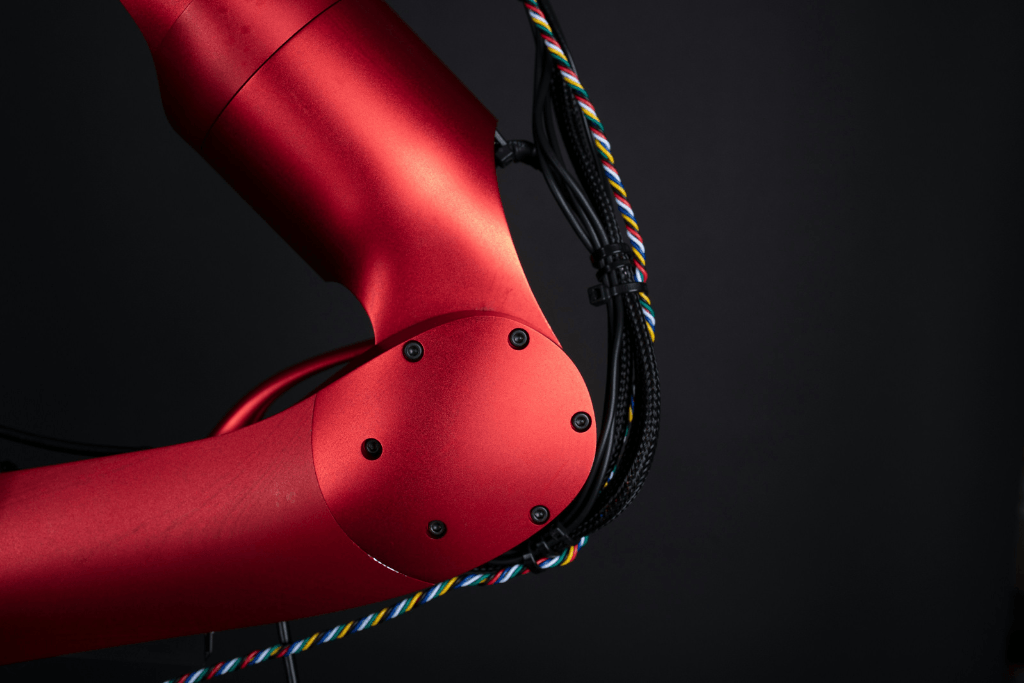

1. Robotic Arms

Robotic arms, designed to handle repetitive tasks and inefficient processes common in factories worldwide, are now revolutionizing construction. They mimic human arm movements, allowing for precise and accurate completion of complex tasks.

For example, the Mule (Construction Robotics) robot is designed to make it easier to lift large blocks. It can pick up materials of all sizes from multiple directions and grip points. And it can work from the back of a trailer or even a truck.

It is also suitable for other construction activities, such as erecting retaining walls (ensuring that large blocks are placed accurately and safely), installing solar panels, or helping with civil construction and landscaping projects when executing tasks on different terrains.

2. Brick Laying Robots

Hadrian X, from the Australian company FBR, consists of a truck with a large 32-meter telescopic arm, capable of placing up to 500 blocks per hour and completing the external and internal walls of a standard house in a single day.

The dimensions of these blocks can reach 60x40x30 cm and weigh 45 kilos. Its dynamic stabilization technology and CAD modeling ensure, according to the manufacturer, a more accurate construction, avoiding the waste of materials and reducing the total costs of the project.

3. Façade Washing and Drilling

Robolift, developed by Norwegian company Nlink, is built on a lifting platform and equipped with a robotic arm that operates a powerful pressure washer for façade washing. With software updates, it can also handle façade inspections, sand washing, sandblasting, or painting.

Nlink also launched the Drilly drilling robot in 2016, a project designed to reduce stress injuries suffered by operators who drill through walls and ceilings.

Thanks to the fact that it is controlled from an app and with a laser, its perforations aspire to be environmentally friendly, damaging fewer roots and underground objects, and generating less dust, dirt and noise.

4. Autonomous Vehicles

Equipped with advanced sensors and navigation systems, autonomous vehicles move around construction sites, transporting materials, lifting objects, and excavating land with minimal human intervention.

For example, a hydraulic excavator named HEAP, modified by the ETH Institute in Zurich, operates autonomously. It uses onboard scanners to map its environment in 3D, enabling AI to construct a stone wall up to 6 meters high and 24 meters long in just one day.

The company Fox Robotics has an autonomous forklift, capable of unloading a trailer full of pallets in less than 50 minutes. FoxBot is equipped with a set of cameras and sensors with which to identify pallets and detect obstacles in real time.

Its firmware allows it to drive with precise control of its speed and position. Even in cramped and chaotic environments, you can create maps automatically and on the fly. All the operator will have to do is open the trailer of the truck and, when necessary, recharge FoxBot with energy.

Baubot, designed by the Fischer company, is a robot that automates fastening and assembly tasks in construction. It allows greater precision in the placement of anchors, which makes it possible to transfer the project plan to the reality of the work.

Thanks to its sensors, the robot detects any deviations from the standard drilling and placement process and responds with a predefined strategy. In addition, it is capable of creating a safety zone around itself to prevent unauthorized entry of personnel into the work area.

5. 3D printing

3D printing enables the construction of high-quality homes more quickly and affordably, potentially redefining community development.

The technology already supports the construction of multi-story buildings through precise material layering. For instance, ICON’s robotic construction system, Phoenix, has 3D printed over 140 houses and structures in the U.S. and Mexico. Phoenix can print an entire building’s envelope, including

foundations and roof structures, and has completed a prototype of an 8-meter- high structure

In addition, 3D printing allows architects to create small-scale models to demonstrate the feasibility and effectiveness of different shapes, surfaces, and façades before they are built. A very effective argument when it comes to defending new design approaches before construction companies.

Robotizing All Phases of a Project

In each of these examples, robotics is intrinsically performing in favor of innovation, productivity, sustainability, and quality control, which affects all phases of a project.

From planning to finishing, robots can perform tasks faster – up to 30% more, according to a study by the Construction Industry Institute – and with greater precision. They also optimize resources, recover recyclable elements and promote the circular economy. Projects require less time and therefore less energy, which reduces costs.

But without a doubt, the quality that will make them essential is safety. Robots are more efficient, do not suffer from distractions or the effects of fatigue, and are less affected by weather factors.

A more controlled environment also means less risk of injury or accidents for human workers. Especially in tasks such as excavations, earthworks or the management of high-risk materials within the construction sites.