Construction is one of the largest industrial sectors, where safety and occupational risk prevention remain paramount concerns. Despite rigorous efforts to ensure workplace safety, too many fatalities and injuries still occur annually.

According to the Occupational Safety and Health Administration (OSHA), the U.S. recorded 5,486 fatal workplace accidents in 2022, equivalent to one worker dying every 96 minutes. The transportation and material movement sectors reported the highest number of fatalities at 1,620, followed by construction and extraction workers who suffered 1,056 fatalities, an 11% increase from the previous year.

The study further reveals that of the ten most common violations found during OSHA inspections of U.S. workplaces, five relate to construction—fall protection, ladder use, scaffolding, fall arrest training, and eye and face protection. Notably, falls are the leading cause of death in construction, while impacts from heavy equipment represent the fourth leading cause of injuries, accounting for approximately 75% of such cases.

Adopting technology solutions to create a connected site environment could drastically reduce accident risks and significantly impact costs. Data from Procore’s construction project management platform suggests that using predictive AI models could yield annual savings of $1.4 million to $3.6 million in the U.S. construction industry alone.

BIM, AI, Augmented Reality and Predictive Analytics

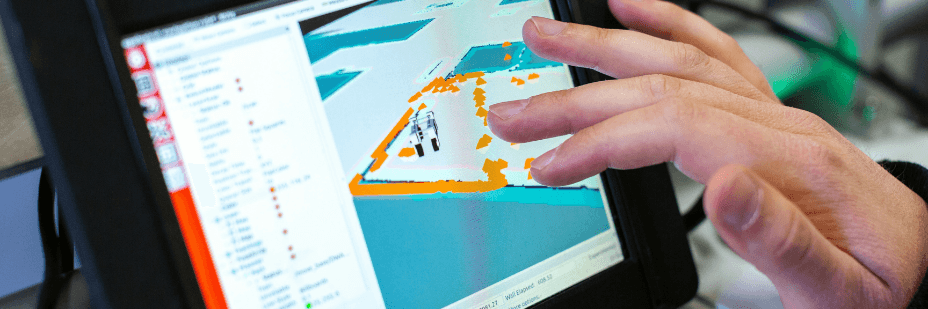

Prevention is a primary area where the impact of emerging technologies like AI is evident in construction. Artificial intelligence and predictive analytics algorithms process vast datasets—including real-time weather conditions, historical safety records, and worker behaviors—to identify patterns and predict potential risks in upcoming projects.

Once construction begins, BIM’s capabilities—including compliance verification, scenario planning, prefabrication, and collision detection—minimize daily accidents. Additionally, BIM aids architects in emergency planning by identifying and delineating the most efficient evacuation routes, enhancing preparedness.

Also, digital twins serve as an invaluable resource for enhancing building safety. They facilitate the identification, understanding, management, and mitigation of construction risks, thereby improving safety by anticipating potential issues throughout the building’s lifecycle.

In addition, augmented and virtual reality technologies enable the creation of highly realistic simulated construction environments. Workers use these technologies to practice tasks like working at heights, operating heavy machinery, or handling hazardous materials. This seamless integration of virtual information with the physical environment aids workers in making informed decisions and effectively navigating potential hazards.

Telematics devices are very useful when operating heavy vehicles, as they allow monitoring of location, speed, driver safety, and engine status—including fuel usage and performance. These systems also enable the assessment of reckless driving behaviors, providing alerts as necessary.

Examples of Construction Safety Innovation

So, how does technological advancement already impact construction sites? Boston-based Suffolk utilizes big data and predictive analytics to foresee accidents before they occur. In collaboration with SmartVid.io, they initiated the Vinnie Predictive Analytics project, which compiles extensive data, including a decade’s worth of images from construction site incidents, to develop a novel accident prevention system.

The results were compelling: the program successfully predicted 20% of all incidents over three years with 80% accuracy.

What proportion of these early warnings could actually prevent accidents? If only 25% of the predicted incidents were avoided, a company managing 50 projects annually could prevent 40 to 100 incidents. With each incident costing approximately $ 38,000 in 2018, this equates to annual savings of 1.5 to 3.8 million.

Addressing the penalties for non-compliance with safety regulations, companies like the American Soter Analytics offer an AI platform that quickly identifies dangers, risks, and compliance breaches.

This AI tool not only detects the specific regulations being violated but also warns of the penalties and suggests corrective actions. It features a chatbot that assists safety managers by getting them direct references to relevant OSHA provisions. Furthermore, organizations can upload their safety policies onto the platform for comparison against OSHA guidelines to ensure compliance.

Leveraging the Transformative Potential of Digitalization

While technological advances of Construction 4.0 are making the sector safer, more efficient, and resilient, significant barriers such as interoperability, data privacy, cybersecurity, regulatory flexibility, and planning remain. Fully understanding these challenges is essential for developing strategies that effectively utilize digitalization in enhancing construction safety.

A key aspect of integrating new technologies involves reforming outdated regulatory frameworks to align with current technological advancements, ensuring seamless integration with existing control systems and processes.

Successful deployment of smart solutions in the construction industry depends on the acceptance of all stakeholders. The technology must be accessible, secure, and designed to enhance the human-machine relationship, allowing workers to improve their skills while simultaneously enhancing system capabilities to better assist professionals.